If your business relies on dock levelers to facilitate the loading and unloading of product, you know that a broken dock leveler is a problem. Maintaining that dock leveler and its related equipment is an important priority if you want to keep operating efficiently. It helps, then, to know how dock levelers work and what the different dock leveler parts are in case you need to replace them. We’ve worked up this handy dock leveler vocabulary list for our customers’ use.

Many Types of Dock Levelers

We covered how different types of dock levelers work in a previous blog. Mechanical dock levelers have far more moving parts than hydraulic or pneumatic dock levelers, and these parts – especially the springs – are under pressure. This pressure, when released, is what operates the leveler. Over time pressure, heat, and cold work to degrade the springs and other parts, and they will have to be replaced. During a lifetime of use, mechanical dock levelers will need much more maintenance and repair than hydraulic or pneumatic levelers for this reason. They are less expensive to purchase and install, but much more expensive to maintain and operate.

If you see that your loading dock door is dented, bent, or otherwise damaged, you need to repair it. Likewise, if the door does not open or close smoothly or well, you should call Beuschel Sales for service. If the door sticks or the seals surrounding the door are broken, it needs repair.

Dock Leveler Vocabulary

The below terms that are useful to know if you want to understand how dock levelers work and how to best determine, based on these concepts, what kind of dock leveler would work for your facility.

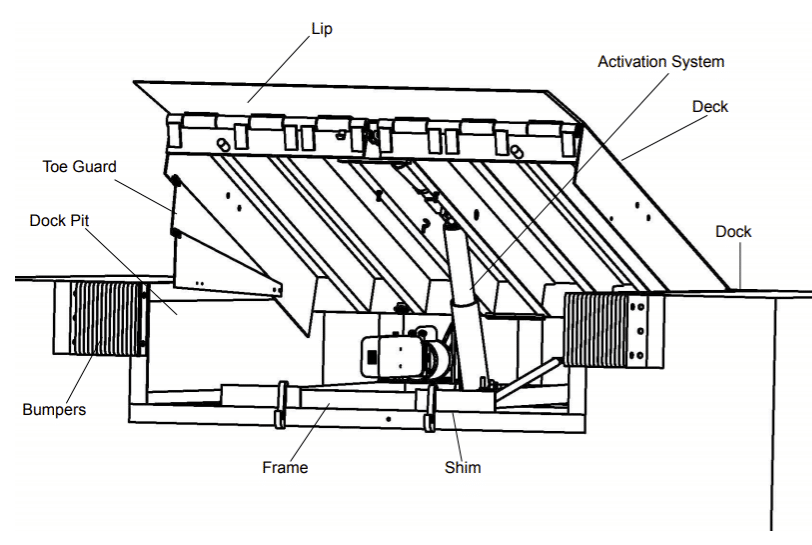

Activation System: This is the system designed to put the dock leveler into operation. The three most common activation systems are mechanical, pneumatic, and hydraulic.

Attachments: Implements added to a fork truck to aid in handling a load. They can be items such as clamps, slip sheet forks and carpet poles. Forklift attachments affect how much the forklift can carry which affects the choice of dock leveler.

Bumpers: Typically made of rubber, bumpers are used to prevent the trailer from bumping into and damaging the building, dock leveler or vehicle restraint.

Capacity: The rating of the load deemed by the manufacturer to be appropriate for the dock leveler’s design, i.e., how much weight and use it can handle.

Deck: The deck, or deck assembly, is the part of the dock leveler structure that the forklift drives over. Decks usually have an anti-skid surface such as a tread plate surface that provides traction for the forklift. At one end of the deck is a hinged lip. The back end of the deck, the end furthest from the truck, pivots.

Dock: The area of a building where trailers load and/or unload their cargo.

Dock Level: The vertical level that conforms to the building’s floor surface.

Dock Pit: The recessed opening in the dock’s concrete floor that accommodates the pit dock leveler. They are usually lined along the edges with structural steel angles embedded in the concrete.

Frame: Also known as the frame assembly. This is the supporting structure for a dock leveler.

Gross Vehicle Weight (GVW): The combined weight of the material handling equipment

(lift truck, pallet jack, etc) and the load. This is the total weight that the dock leveler accommodates when the forklift passes over it.

Lip: Also known as the lip assembly, the lip is usually pivotally attached to the deck assembly. It pivots from a vertical stored position to a position that rests on the trailer’s floor. Lips usually have a tread plate that is similar to the deck.

Load: The weight of a typical individual pallet on a transport vehicle. When calculating capacity, typically there are a maximum of (20) twenty loads per transport vehicle.

Shift: The company’s working shift. When calculating capacity, a typical capacity calculation would involve a maximum of (8) eight trailers per shift.

Shim: The steel plates that can be used to help level pit-mounted dock levelers. They can be put under the frame structure and welded in place to create a structural load path to the building’s foundation.

Toe Guard: A shield mounted flush to the side of a deck assembly to provide toe protection when the dock leveler is above dock level.

Transport Vehicle: A cargo carrying vehicle such as a truck, semi-trailer, trailer or railcar.

Working Range: The recommended range of vertical travel above and below dock level for which loading and unloading can take place.

If you have questions about what capacity dock leveler would be best for your operation, we would be happy to help you determine capacity and advise you on a dock leveler choice that will accommodate it. Call us at 616-520-8680! We are always happy to talk dock levelers with our customers.